In a hyper-competitive business environment, how well you run your business can make or break it. Whether it’s managing supply chains, optimising inventory levels, or delivering consistent quality to customers, operations management is what turns your business strategy into action.

Understanding operations management

Operations management is an umbrella term for all the planning and coordination of business processes that transform your inputs – e.g., labour, materials, capital – into outputs such as goods and services. Not only can it give you a competitive advantage, but it can also help your day-to-day operations run more smoothly and support your company’s broader strategic vision.

An operations manager is someone who spends their time streamlining production, managing inventory, coordinating logistics, allocating resources, and handling quality control. The position itself is vitally important in industries such as manufacturing, logistics, healthcare, construction, and retail, but the principles of operations management remain the same across virtually every sector.

High-quality operations management essentially involves mastering both practical, day-to-day oversight and strategic thinking. It’s a way to connect people, processes, and technology to deliver the best possible outcomes and ensure resources are used effectively and at the right time.

The importance of management and operations

Strong operations management can be beneficial for businesses of any size, but especially when you’re in a growth phase or dealing with more complex operations than usual. Here’s why it matters:

It drives greater efficiencies

At its core, operations management is about maximising efficiency. That includes everything from reducing waste, managing your time more effectively, and – perhaps most importantly of all – maximising the value of your existing resources. Fine-tuning your production processes or automating jobs, for example, can cause knock-on effects that result in noticeable improvements in output (without blowing out costs).

It helps reduce costs

On that note, operations managers are responsible for monitoring costs across the entire business, reducing overheads, optimising inventory levels, minimising downtime on machinery, and sourcing better-value suppliers. Every dollar saved through operations improvement helps your bottom line.

It leads to better customer satisfaction

Solid operations translate to faster delivery times and better quality products. And that also means a smoother experience for your customers. All these factors can contribute to higher customer retention. Whether your business ships products or sells professional services, meeting customers’ expectations every time is an invaluable competitive advantage.

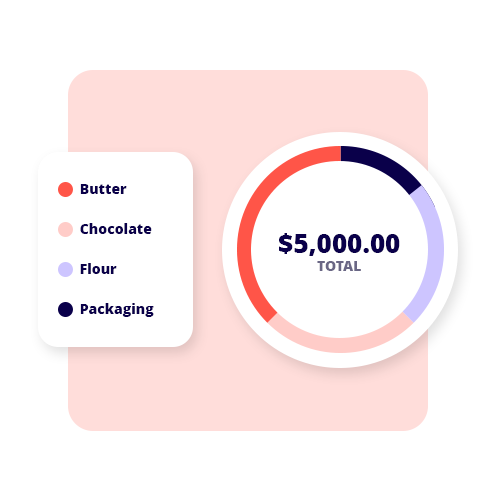

It formalises inventory management

Holding too much inventory ties up capital, but too little can mean you end up losing sales or missing deadlines. So use forecasting tools and smart reorder points to stay on top of stock management.

It supports your long-term growth

As your company grows, so too does the complexity of your operations. A solid operational framework makes it easier to scale up processes and onboard staff. It’ll also put you in a better position to readjust to changing market demands.

What does an operations manager do?

Depending on the size and nature of your business, your operations manager might wear many different hats:

- Oversight: Overseeing day-to-day business processes and workflows.

- Project management: Monitoring supply chain logistics and delivery timelines.

- Quality control: Ensuring consistency across products/services.

- Teamwork: Working on collaboration to boost productivity.

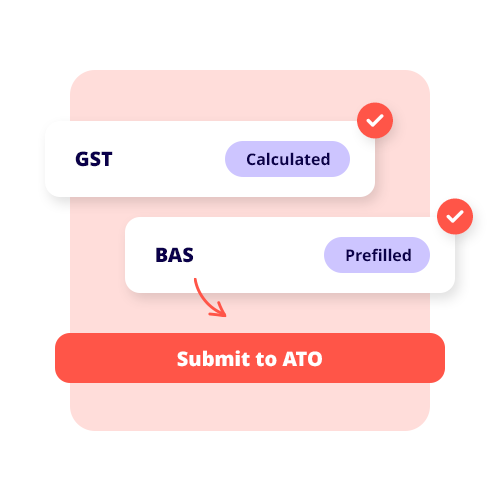

- Analysis: Using data and reporting tools to track performance and bottlenecks.

- Finance: Forecasting budgets and handling operating costs.

In short, the operations manager is the go-to person for keeping your business engine running.

Core areas of operations management

Process optimisation

Focused on improving how work gets done. Usually involves getting rid of any inefficiencies, automating tasks and redefining workflows to produce faster (or better) results.

Supply chain coordination

Ensures that raw materials are ordered and converted into products as quickly as possible. A streamlined supply chain helps you stay agile and competitive in the market.

Quality control

The practice of keeping good product or service standards. This can involve testing, inspections, or continuous feedback loops. Quality management is central to building trust with your customers.

Resource management

Allocating labour, equipment and time to make sure your production targets are always met – without overspending. This area also includes capacity planning as well, so that the business has the right resources available to meet future demand.

Technology and automation

Modern operations management leverages tools like enterprise resource planning (ERP) systems, inventory tracking software, workflow automation platforms, and many others. Technology like this can help you centralise all your disparate data and reveal truly valuable insights for future decision-making.

Trends shaping operations management today

- Data-driven decision-making: More businesses are using real-time analytics to spot inefficiencies and make proactive, rather than reactive, decisions.

- Sustainability in operations: Cutting down on waste and rolling out eco-friendly practices are now seen as both ethical and commercially savvy.

- Flexible inventory systems: With global supply chains still grappling with disruptions and delays in the post-COVID world, many businesses are shifting towards more adaptable, just-in-time inventory management models.

- Remote and hybrid workforces: Operations managers are adapting to new ways of managing their teams and schedules remotely.

Operations management encompasses much more than simply cutting costs and improving existing systems. When managed intelligently, your operations will become a source of strength to drive growth and deliver real value to your customers.